Navigating the Future of Industrial Safety: Trends to Watch This Year

As the first half of 2024 draws to a close, the landscape of industrial safety is evolving rapidly. Emerging technologies and new regulations are set to transform how businesses ensure workplace safety. Staying ahead of these trends is crucial for maintaining compliance and protecting employees.

The second half of 2024 brings forth a multitude of changes in industrial safety practices that you need to be aware of. From advancements in technology to shifts in regulatory frameworks, understanding these trends will help you navigate the complexities of workplace safety. Let’s dive into some of the key developments that are shaping the future of industrial safety.

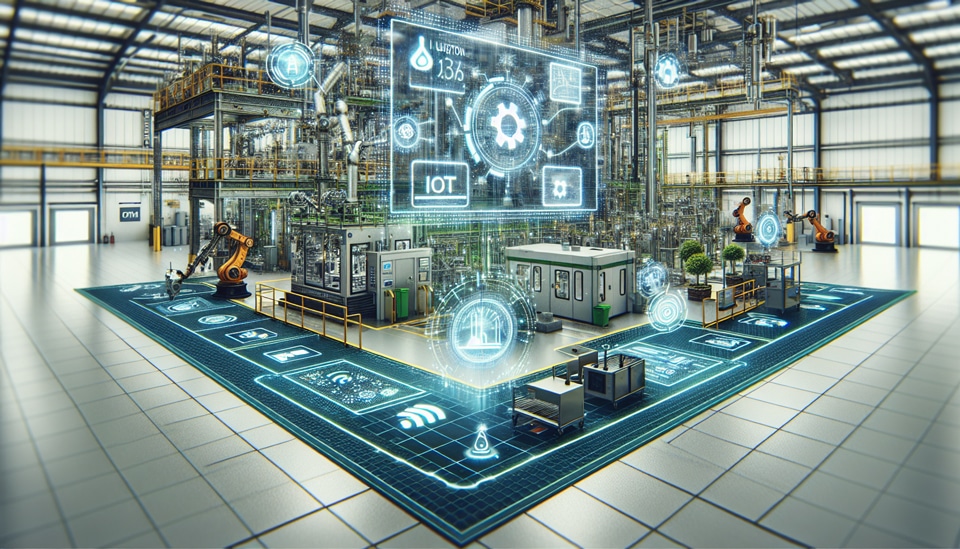

The Rise of Smart Technology

Smart technology continues to revolutionize industrial safety protocols. Wearable devices, IoT sensors and AI-driven analytics are becoming integral components of safety management systems. These technologies provide real-time data and predictive insights, enabling proactive measures to prevent accidents and incidents. For example, safety mats are now equipped with sensors to detect pressure and alert workers to potential hazards instantly. This integration of smart technology not only enhances safety, but also optimizes operational efficiency. Learn more about safety mats in the workplace.

Another significant advancement in smart technology for industrial safety is the implementation of augmented reality (AR) systems. AR applications are being used to provide workers with real-time visual guidance for complex tasks, reducing the risk of errors and accidents. For instance, maintenance technicians can now use AR headsets to overlay schematics and safety protocols directly onto equipment they’re servicing. This not only improves accuracy but also ensures that safety procedures are followed meticulously, even in challenging environments.

The integration of artificial intelligence (AI) and machine learning (ML) in safety systems is another notable trend. These technologies are being used to analyze vast amounts of data from various sensors and historical incident reports to identify patterns and predict potential safety hazards. For instance, AI-powered systems can now forecast equipment failures before they occur, allowing for preemptive maintenance and reducing the risk of accidents. Moreover, ML algorithms are enhancing the capabilities of surveillance systems, enabling them to detect unsafe behaviors or conditions in real-time and alert supervisors immediately. This proactive approach to safety management is significantly reducing incident rates and creating safer work environments across industries.

Enhanced Regulatory Compliance

With the introduction of stricter safety regulations, compliance has never been more critical. New standards are being implemented across various industries to ensure higher levels of worker protection, something that is essential when it comes to keeping employees safe, healthy and happy. This includes stricter guidelines for equipment maintenance, mandatory safety training programs and more rigorous inspection protocols. Businesses must stay updated with these changes to avoid penalties and ensure a safe working environment.

One of the most notable changes in regulatory compliance for the second half of 2024 is the increased focus on cybersecurity in industrial settings. As industrial systems become more interconnected, the risk of cyber attacks that could compromise safety systems has grown significantly. New regulations are requiring companies to implement robust cybersecurity measures to protect their safety-critical systems from potential breaches. This includes regular security audits, encrypted communication protocols, and comprehensive incident response plans. Compliance with these new cybersecurity standards is becoming as crucial as traditional safety regulations in ensuring overall workplace safety.

Focus on Mental Health and Well-Being

Recognizing the importance of mental health in the workplace is another significant trend that has been building over the past two to three years. Industrial environments can be stressful, and addressing mental well-being is now considered a key component of overall safety strategies. Companies are increasingly offering mental health resources, stress management programs, and creating a supportive work culture to help employees cope with occupational stressors. This holistic approach not only enhances worker satisfaction but also reduces the risk of accidents caused by mental fatigue or distraction.

Companies are seeing a rise in the use of technology to support mental health initiatives in industrial settings. Virtual reality (VR) applications are being deployed to provide immersive stress reduction experiences during break times. Additionally, AI-powered chatbots are being integrated into company intranets to offer 24/7 mental health support and resources. These technological solutions complement traditional employee assistance programs, providing workers with immediate access to mental health tools and support. By leveraging these innovative approaches, companies are creating more resilient workforces better equipped to handle the challenges of industrial environments.

Sustainability and Environmental Safety

As sustainability becomes a priority globally, its influence on industrial safety practices cannot be overlooked. Businesses are now focusing on eco-friendly practices that also contribute to a safer workplace. This includes reducing hazardous waste, using sustainable materials, and implementing energy-efficient processes. By prioritizing environmental safety, companies not only comply with regulations but also promote a healthier environment for their workforce.

The concept of circular economy is gaining traction in industrial safety practices this year. Companies are now designing their products and processes with end-of-life considerations in mind, which not only reduces environmental impact but also enhances worker safety. For example, manufacturers are developing safer, biodegradable alternatives to traditional harmful chemicals used in industrial processes. This shift towards circular economy principles is leading to the creation of closed-loop systems that minimize waste and exposure to hazardous materials. As a result, workers benefit from reduced exposure to potentially harmful substances, while companies improve their environmental footprint and operational efficiency.

Have you read?

Best Fashion Schools. Best Universities. Best Medical Schools. Best International High Schools. Countries: Most Female Billionaires.

Bring the best of the CEOWORLD magazine's global journalism to audiences in the United States and around the world. - Add CEOWORLD magazine to your Google News feed.

Follow CEOWORLD magazine headlines on: Google News, LinkedIn, Twitter, and Facebook.

Copyright 2025 The CEOWORLD magazine. All rights reserved. This material (and any extract from it) must not be copied, redistributed or placed on any website, without CEOWORLD magazine' prior written consent. For media queries, please contact: info@ceoworld.biz