All you need to know about electrical busbars

In the era of a highly dynamic and fiercely competitive business landscape, a reliable power distribution infrastructure is crucial to running operations seamlessly within commercial settings.

The electric busbar is a sophisticated technological component that can help achieve the high efficiency of power distribution systems across multiple industries and sectors.

Let’s check what an electric busbar is, what makes it so powerful, and where this technology can be applied.

What is an electric busbar?

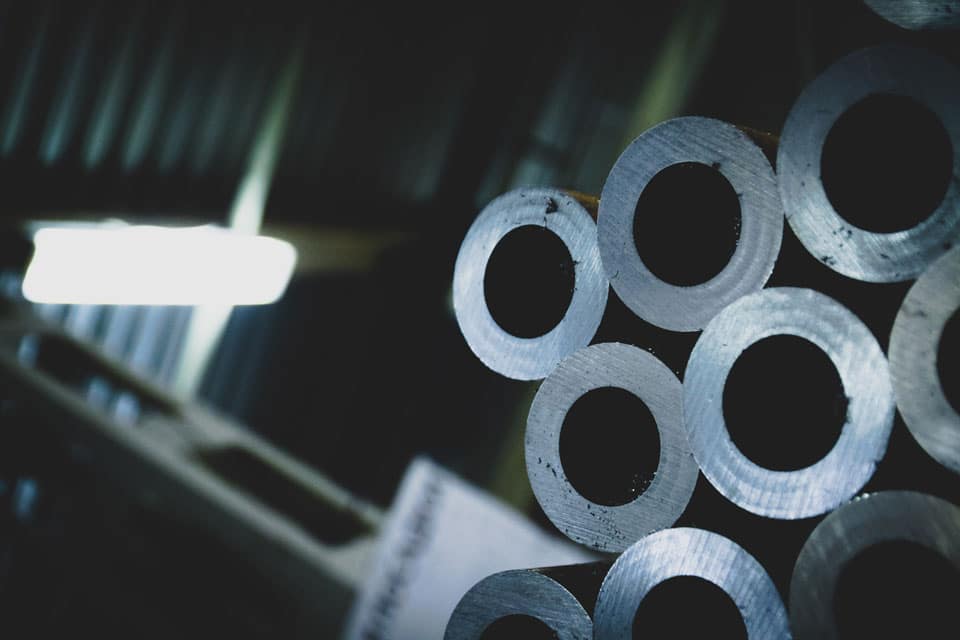

According to its definition, an electric busbar is a rigid conductor that plays the role of a central point for electrical power distribution. Usually it is made of aluminum or copper, which allows it to transmit electricity in a low-resistant way.

It is also worth mentioning that busbars can carry massive currents and can take multiple forms, such as:

- flat strips,

- rectangular bars,

- cylindrical rods,

- tabular,

- elliptical,

- U-shaped,

- T-shaped,

- and many more.

Their final size is influenced by the capacity that is required for the specific use case.

What makes electric busbars such a powerful technology?

Effective power distribution

First of all, electric busbars provide businesses with a superior method of power distribution than traditional wiring systems. They not only enhance overall electrical system reliability but also:

- help maintain stable voltage levels,

- minimize voltage drops,

- significantly limit the risk of electrical failures,

- promote the even distribution of current,

- lower the likelihood of electrical malfunctions.

Improved electrical safety

Another huge advantage of electric busbars is the enhanced electrical safety, which is crucial for the well-being of employees. By offering effective electrical insulation and, as a result, a low risk of short circuits or electric shock, they assist in meeting safety regulations and standards.

Space savings

Electric busbar implementation also allows companies to save space. It allows them to create a compact and well-organized electrical infrastructure layout, eliminating the need for scattered loose wires that often characterize conventional wiring setups.

What is more, such an effective electrical layout not only contributes to space conservation but also leads to substantial reductions in both installation time and material expenditures.

Enhanced heat dispersion

Finally, thanks to the expansive surface area of electric busbars, they enable efficient heat dispersion. It resolves the problems related to excessive heat buildup and, consequently, enhances the durability and dependability of electrical elements.

Where can you apply electric busbars?

As already mentioned, there are numerous use cases for the electric busbar concept, and multiple industries can benefit from implementing it within their infrastructure.

That being said, electric busbars:

- enable effective electrical power distribution in buildings, commercial facilities, and industrial settings,

- facilitate efficient power distribution within data centers,

- connect diverse elements in solar and wind power installations,

- increase the reliability and efficiency of power distribution and control in electric vehicles, or railways.

All in all, an electrical busbar can help businesses achieve reliable and highly effective power distribution systems. It can be applied in buildings, industrial settings, or renewable energy installations and contribute to improved safety, decreased cost, and enhanced overall electrical system reliability.

Have you read?

Revealed: The Biggest Beer Companies in the World, 2023.

Ranked: Most Popular Dog Breeds in the U.S. of 2023.

Revealed: Countries With the Highest Suicide Rates, 2023.

Ranked: These Are The Most Dangerous Jobs in the World, 2023.

America’s Best Investment Advisory Firms, 2023.

Bring the best of the CEOWORLD magazine's global journalism to audiences in the United States and around the world. - Add CEOWORLD magazine to your Google News feed.

Follow CEOWORLD magazine headlines on: Google News, LinkedIn, Twitter, and Facebook.

Copyright 2025 The CEOWORLD magazine. All rights reserved. This material (and any extract from it) must not be copied, redistributed or placed on any website, without CEOWORLD magazine' prior written consent. For media queries, please contact: info@ceoworld.biz