A Guide To Selective Laser Sintering Technology

3D printing, also known as additive manufacturing, is rapidly transforming the manufacturing industry with its efficient and flexible approach to product design and production. Among the various 3D printing technologies available, selective laser sintering (SLS) is one of the most promising and versatile. In fact, in 2020, the SLS 3D printer market was worth US$353.6 million and is projected to expand at a compound annual growth rate (CAGR) of 22.19%, equivalent to a market size of US$1,438.37 million by 2027.

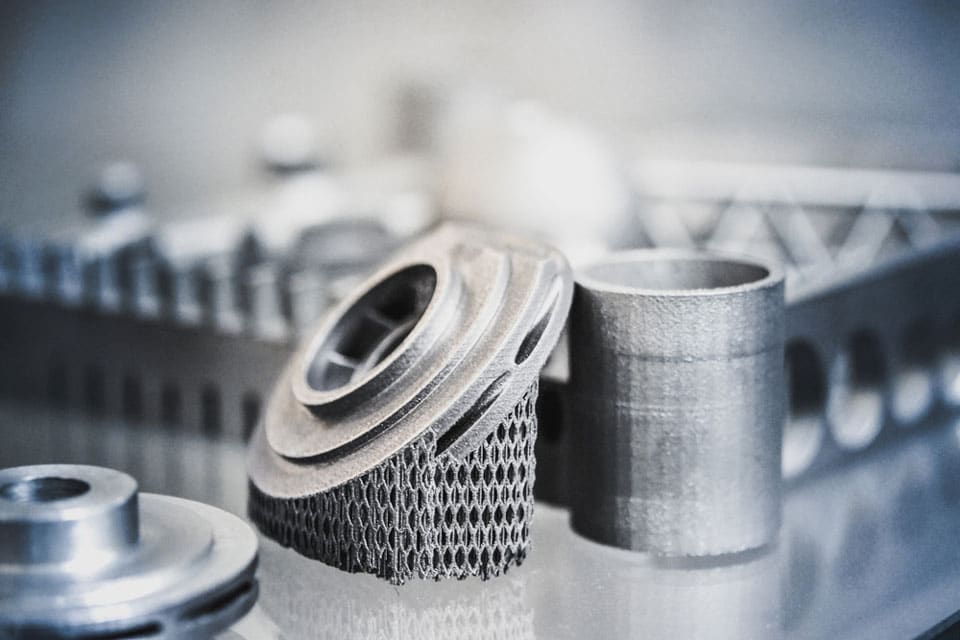

SLS creates 3D objects by selectively sintering (or fusing) layers of powder using a laser. The process offers several advantages over traditional manufacturing methods, including creating complex shapes and geometries that are difficult or impossible to achieve using other methods.

How does SLS technology work?

Even when you’ve already decided to invest in selective laser sintering, you’re probably wondering what the process entails after getting an SLS 3D printing quote. Back in the 80s, a groundbreaking process known as SLS was invented and patented by a mechanical engineering professor, Joe Beaman, and his brilliant undergraduate student, Carl Deckard, at the University of Texas. This dynamic duo forever changed the course of 3D printing history.

As mentioned earlier, SLS technology works by selectively sintering (or melting) layers of powder using a laser. The process starts by spreading a thin layer of powder material (usually nylon or polyamide) onto a build platform. The laser then scans the surface of the powder, selectively melting the powder particles together to create the desired shape.

Once the first layer is complete, another layer of powder is spread on top, and the laser scans again to melt the powder particles and fuse them with the layer below. Layer by layer, the 3D printing process is repeated until the object is fully formed. After printing, the object is left to cool and harden in the build chamber. Once sufficiently cooled, the object can be removed from the build platform and cleaned of any excess powder.

Advantages of SLS technology

There are several advantages to using SLS technology over traditional manufacturing methods:

- High precision

Using other methods, SLS technology can create highly precise parts with intricate geometries that are difficult or impossible to achieve. Since this innovation has a great support structure, it offers a design playground where complexity knows no bounds.The technology empowers designers to venture into uncharted territories, unlocking an array of design possibilities that were once unattainable with traditional methods. What’s more, SLS design is a game-changer as it allows designers to combine intricate assemblies that previously required multiple parts into one seamless masterpiece.

- No need for support structures

One of the many unique features that sets SLS apart from other 3D printing processes like fused deposition modeling (FDM) and stereolithography (SLA) is that it doesn’t demand any fancy support structures. The secret lies in the ever-present unsintered powder during the printing process, making it a true standout in the additive manufacturing world. Unlike other 3D printing methods, SLS doesn’t require support structures to hold up the part during printing. This makes it possible to print complex geometries without the need for post-processing. - Variety of materials

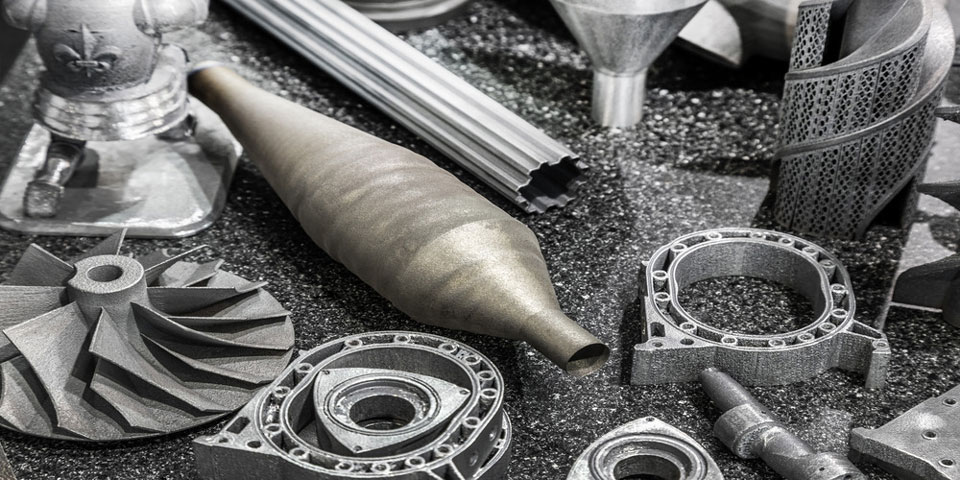

SLS can use a wide range of materials, including nylon, polyamide, and even metal powders. This allows for a wide range of applications and the ability to create objects with different properties.Another factor that makes SLS a game-changer is that it enables designers to create prototypes and end-use parts using the same machine and materials. This feat was previously impossible with traditional methods. This seamless and hassle-free modification process translates to high cost and time savings, making SLS a clear winner in the 3D printing world.

- Reduced waste

SLS technology produces very little waste since any excess powder can be reused for future prints, not to mention reduced product development time. Gone are the days of endless product development cycles, thanks to SLS 3D printing. With its low-cost prototyping capabilities, engineers can get their hands on early-stage parts without breaking the bank or waiting for time-consuming tooling and setup processes.Plus, with the ability to produce end-use parts using the same machine, SLS is the go-to choice for low-volume production runs. With the power to tweak and test prototypes in just a few days, SLS can help you take the fast lane to production and beyond.

- Scalability

SLS technology can produce small quantities of parts or large batches, making it suitable for prototyping and mass production. Moreover, SLS printing has a clear advantage over traditional manufacturing because it allows creators to make complex or delicate objects without needing molds or tools. This makes it an excellent option for anyone who wants to create something with great detail and accuracy.SLS printing is a highly specialized technique that differentiates it from other printing methods. To get the most out of SLS printing, it’s essential to have a deep understanding of its workings and nuances. Mastery of SLS printing can yield unparalleled precision and quality in the final product.

Disadvantages of SLS technology

While selective laser sintering technology has numerous advantages and has transformed the world of 3D printing, it’s not without its limitations. As with any technology, SLS printing also has its fair share of disadvantages that need to be considered. These limitations can impact the final product’s overall cost, production time, and quality. Therefore, it is crucial to be aware of the potential drawbacks of SLS technology to make an informed decision when choosing a printing method.

Some of these disadvantages include the following:

- High cost: SLS technology is generally more expensive than other 3D printing methods due to the materials’ expense and the equipment’s complexity.

- Longer print times: SLS printing can be slower than other 3D printing methods due to the need to scan and melt each layer of powder.

- Limited color options: SLS printing is typically limited to a single color or material, unlike other 3D printing methods that allow for multiple colors or materials in a single print.

- Limited size: SLS technology is limited by the size of the build chamber, which can restrict the size of the objects you can print.

Upon closer inspection, some of the perceived disadvantages of SLS printing may not be as problematic as you may think. Factors such as cost and time may be offset by the technology’s superior precision and quality. Furthermore, certain limitations, such as the need for support structures, can be addressed through post-processing techniques.

Applications of SLS technology

Engineers and manufacturers from various industries trust SLS 3D printing because of its ability to produce robust and practical parts. SLS technology has a proven track record of creating high-quality products that meet the requirements of diverse industries. Its popularity is due to its combination of strength, precision, and durability, making it a go-to solution for many professionals.

That said, SLS technology has a wide range of applications in various industries, including:

- Aerospace: Through this technology, you can create lightweight and complex parts for aircraft and spacecraft.

- Automotive: Selective laser sintering can help create vehicle parts, including engine components, interior features, and even entire car bodies.

- Medical: SLS technology can create prosthetics, implants, and other medical devices requiring high precision and customization.

- Architecture: Businesses can use SLS technology to create intricate and complex architectural models and prototypes.

- Consumer products: Manufacturers can produce custom phone cases, jewelry, and other consumer products.

- Industrial manufacturing: SLS technology can be used to manufacture tooling, molds, and other industrial parts.

SLS printing has become more accessible to businesses due to recent machinery, materials, and software advancements. As a result, more and more companies can now leverage the benefits of SLS printing that were once limited to a few high-tech industries.

These advancements have made the technology more cost-effective, efficient, and user-friendly, making it easier for companies to adopt it into their operations. This has resulted in a significant increase in the use of SLS printing across different industries, proving its versatility and applicability in diverse settings.

Final words

Selective laser sintering technology is a powerful and versatile 3D printing technology that offers several advantages over traditional manufacturing methods. While it may be more expensive and time-consuming than other 3D printing methods, the ability to create highly precise and complex parts makes it an ideal choice for various applications in various industries. As technology continues to evolve, you can expect to see even more innovative applications in the future.

Have you read?

Richest Actors In The World And Their Net Worth, 2023.

Richest Tennis Players In The World And Their Net Worth, 2023.

Study: Music successful CEOs and c-level executives listen to, 2023.

Which are the healthiest countries in the world for 2023?

Best Business Schools In The World For 2023.

Bring the best of the CEOWORLD magazine's global journalism to audiences in the United States and around the world. - Add CEOWORLD magazine to your Google News feed.

Follow CEOWORLD magazine headlines on: Google News, LinkedIn, Twitter, and Facebook.

Copyright 2025 The CEOWORLD magazine. All rights reserved. This material (and any extract from it) must not be copied, redistributed or placed on any website, without CEOWORLD magazine' prior written consent. For media queries, please contact: info@ceoworld.biz