3D Printers Speed Improves As The Braces Industry changes

Braces are a dreaded accessory for any teenager, but they do an important job. The sessions involved with getting and keeping braces are tedious, and most report pain from the procedure. While confidence should not come from if you have braces or not, with the cruelty of preteens, it can be difficult to smile or interact with your braces, and not be teased.

While this does not reflect the power and practice of braces, it is still a reality for children. The world is shifting away from the metal braces but has done so quietly in the air of recent technological advancements.

Invisalign is a life-saver for those with crooked teeth who do not want large metal braces becoming their distinguishing factor.

Why Are Plastic Braces Just Now Making An Appearance?

Let’s examine the timeframe of braces, as we know them today. The large metal aligners debuted in the 1970s. Then, these devices have been the main tool to straighten teeth in the next 40 years to follow.

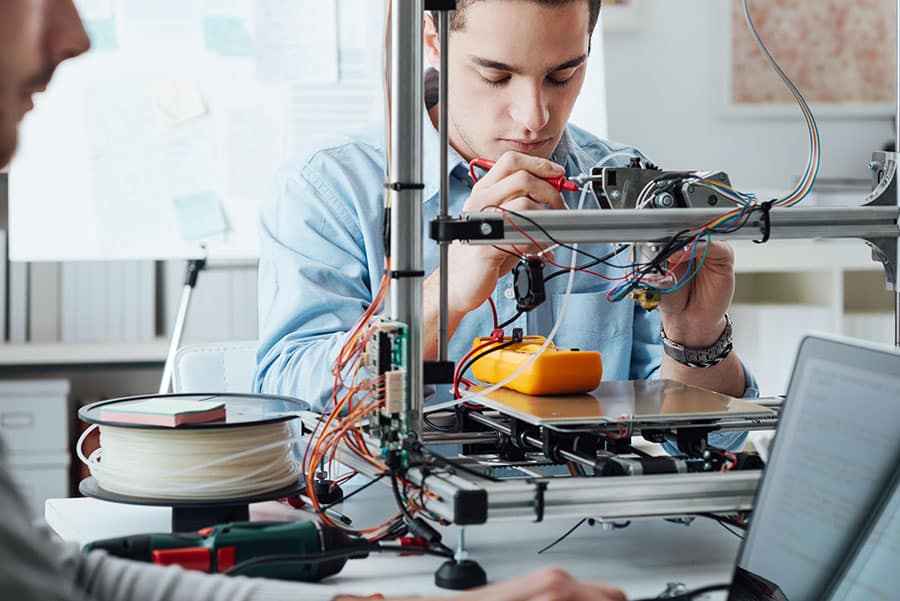

Plastic aligners are made possible thanks to the advancement of technology. Or, more specifically, the invention of the 3d printer. With a 3D printer, you can take a scanned image of your teeth and produce a printed mold to fit on them.

As soon as 3D printers made their appearance, stocks in them skyrockets, seeming like a regular household tool soon people all over the world will have. 3D printing is not inexpensive, and it has yet to be starred in regular home life, but they are heavily used in the scientific and health communities.

It is not true that every profession can benefit from the use of 3D printing. Companies that have little to none physical products, like Diamond and Diamond Law Offices, do not need a 3D printer to move business along. That does not mean there will not be a future use of 3D printing in law that will appear in the future.

Like aligners, dentures are not one-size-fits-all. Each mouth is different need customization. So, 3D printing is opening the door to mass-produced aligners and dentures that are more cost-efficient and specialized.

The Evolution of the 3D Printer

One of the main problems with 3D printers are their speed. Since they priory could not produce at the speed of assembly lines, the systems are not valuable to companies for large orders, or mass-production.

Now, the competition is on, with multiple companies advancing the automation to compete with traditional manufacturing. One of these companies is Desktop Metal. They are currently valued at $1.5 billion and is producing large metal-printing machines. Its machines can make more than 500 metal parts in one day.

In comparison, General Electric has 3D metal printing machines, but they only can complete 12 parts a day. Another innovative aspect of Desktop Metal’s printing, is the type of metal they are producing. There is aluminum, stainless steel, and many others that can be ‘printed’ at assembly line speeds.

3D printing is in the midst of steady growth. It took a leap last year by 33%, and has a value of almost $10 million. This is just the early stages of growth, and it is projected to even become more valuable with time, and speedy operation implementations.

Every manufacturing industry is using this growing expertise of 3D printing. Once the materials produced and speeds needed for profit are available, the traditional assembly line method will go out of style.

This is clearly the projection of Aligners. These plastic devices are used by many people, all over the world. When they are more easily produced, they will become cheaper for consumers, and braces will surely stop being the main form of teeth straighteners.

Have you read?

America’s Top 10 CEOs And Executives With The Highest Salaries In 2018.

These Are America’s Top 10 Largest Companies By Revenue, 2019.

Women CEOs In The Fortune 500 Are At A Record High.

These Are The Most Famous Streets In The World.

Why Compliance Is Now a Personal Issue for CEOs by David Wagner.

Bring the best of the CEOWORLD magazine's global journalism to audiences in the United States and around the world. - Add CEOWORLD magazine to your Google News feed.

Follow CEOWORLD magazine headlines on: Google News, LinkedIn, Twitter, and Facebook.

Copyright 2025 The CEOWORLD magazine. All rights reserved. This material (and any extract from it) must not be copied, redistributed or placed on any website, without CEOWORLD magazine' prior written consent. For media queries, please contact: info@ceoworld.biz