Engineering Innovations in Auto Repair: Faster, Safer, More Reliable

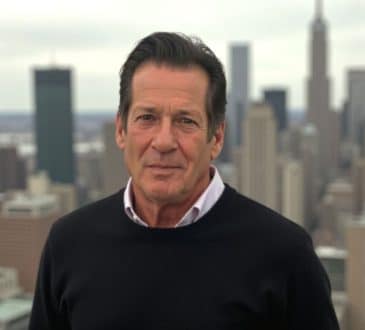

Talented entrepreneur, innovator and engineering manager Vitalii Novitskii’s Cold Glue Development has led to increased efficiency and durability.

In the highly competitive and growing automotive aftermarket industry, estimated to reach $529.88 billion by 2028, efficiency and sustainability are crucial for staying ahead. Traditional dent repair methods are slow and prone to risks such as damaging paintwork or causing burns, which increases both service time and costs for businesses. To solve this issue, industry leaders are seeking innovations that streamline the repair process and reduce costs.

One such development is the “cold glue” system for Paintless Dent Repair (PDR), an approach that has gained attention for its potential to address these longstanding issues. Introduced by engineering manager and entrepreneur Vitalii Novitskii, this system emerged as a response to the limitations of hot glue techniques, offering a faster and more controlled alternative. “Before our cold glue concept, technicians had to wait for the glue to cool and risk damaging the paintwork in the process. Our system eliminates these inefficiencies, making repairs not only faster but also safer,” says Novitskii. Now utilized by a majority of PDR technicians, cold glue represents a shift in how auto repairs are conducted—but its significance goes beyond mere efficiency.

The environmental implications of this method are equally important. Cold glue requires no electricity, which reduces energy consumption, and it eliminates the need for chemicals traditionally used in the repair process. These attributes make it an appealing option for businesses looking to meet the demands of an increasingly eco-conscious market. Recent reports have indicated that industries focused on reducing their environmental impact, like auto repair, are well-positioned to capture a growing segment of consumers who prioritize sustainability. In this context, cold glue’s rise is emblematic of the broader push toward green innovation.

What is particularly notable about Novitskii’s approach is his strategic decision-making regarding intellectual property. Rather than patenting the cold glue formula, Novitskii focused on securing patents for the technical innovations that support its use. “We wanted to ensure that while our glue remains unique, the overall process would be difficult to replicate without our specific technology,” Novitskii explains. This strategy has not only protected his company’s market position but also encouraged the adoption of similar innovations across the industry.

This approach has allowed Novitskii’s company, Glexo, to expand globally, collaborating with international brands and distributing its products in over 50 countries. However, the widespread use of cold glue is not simply a story of business success; it reflects how small, incremental improvements can influence an entire industry. By simplifying the dent repair process, cold glue has encouraged other players in the PDR sector to rethink their own approaches to efficiency and sustainability.

“Innovation doesn’t always mean creating something completely new. Sometimes, it’s about perfecting what already exists and making small, continuous improvements that lead to major breakthroughs,” says Novitskii. His philosophy underscores the importance of gradual innovation in industries that are slow to adopt new technologies, like auto repair.

In addition to its practical applications, the cold glue system has had a tangible economic impact. Reduced repair times, fewer errors, and lower material costs have collectively saved the industry billions of dollars. Furthermore, the technology’s ease of use has inspired other professionals to adopt more streamlined, efficient methods of repair.

Looking ahead, as the auto repair industry continues to evolve, the adoption of technologies like cold glue will likely grow. With environmental and efficiency standards becoming central to industry practices, innovations like these are paving the way for a more sustainable future. Novitskii’s contributions serve as an example of how targeted, thoughtful innovations can push industries forward without the need for sweeping, disruptive changes.

In an industry historically slow to innovate, cold glue’s success demonstrates the value of incremental progress. As businesses around the world seek out more efficient practices, the PDR industry’s future looks promising, with cold glue technology serving as a critical part of that evolution.

Have you read?

World’s Most Innovative Countries, Best Fashion Schools. Best Universities. Best Medical Schools. Best International High Schools. Countries: Most Female Billionaires.

Bring the best of the CEOWORLD magazine's global journalism to audiences in the United States and around the world. - Add CEOWORLD magazine to your Google News feed.

Follow CEOWORLD magazine headlines on: Google News, LinkedIn, Twitter, and Facebook.

Copyright 2025 The CEOWORLD magazine. All rights reserved. This material (and any extract from it) must not be copied, redistributed or placed on any website, without CEOWORLD magazine' prior written consent. For media queries, please contact: info@ceoworld.biz