Assembly Line Robots: All You Need To Know

One of the most significant innovations in the 20th century is the assembly line because it has powerfully shaped the industrial world into what it is today.

In fact, businesses that do not adopt the emerging trends might face extinction in the near future. The assembly line was one of the dominant driving force for the integration of automobiles into the American Society and the world at large.

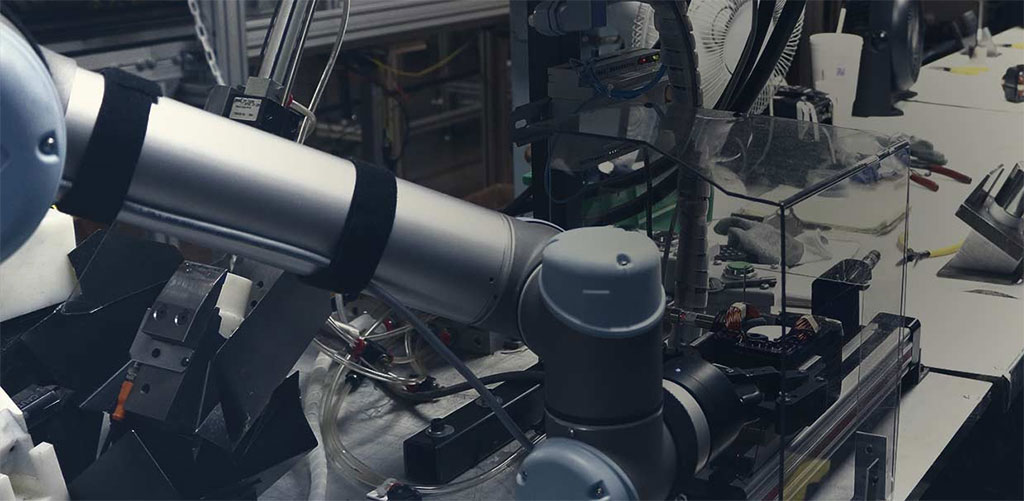

The advancement of technology saw the creation of assembly line robots thus reaching an entirely new level of sophistication in the automotive industry.

This is because these robots occupy a sweet spot between humans and ‘hard’ or dedicated automation when it comes to putting parts together. They also come with a plethora of benefits. For instance, assembly robots not only move faster than humans but also with greater precision.

Similarly, they can be reconfigured quickly and as often as needed since it only requires a change of the program. They’re also a low-risk investment that simultaneously satisfies finance, quality and manufacturing demands.

Myth vs. truth about assembly robots

It is a common myth that assembly robots are stealing jobs from Americans and other humans across the globe. However, this is not true because, for American products to compete with the rest of the world, it is necessary to cut the cost of automation.

When products are competitive, then manufacturing remains local and companies employ more people to occupy high-level and better occupations.

Keeping manufacturing within one’s country creates a need for higher paid and higher skilled jobs to maintain these systems and operate specified programs.

The different types of assembly line robots

Assembly line robots come in these three types of configuration:

- The modern ‘Delta’ configuration

- The four-axis ‘SCARA’ robots

- The six-axis articulated arms

The delta robot which resembles a ceiling mounted spider uses motors in the base to move its three linked arms. Even though payloads are less than those of robots with articulated designs, the delta remains a machine that has unrivaled speed and acceleration.

Different types of assembly robots can be specified in regards to force sensing and vision systems. Using vision, a robot can be guided to pick up a component from a conveyor. This reduces or even eliminates the needed for having a precise pick-up location. Also, visual serving enables the robot to translate or rotate one piece and make it fit with the others. Force sensing is used to assist the robot with operations involving part assembly such as insertion, giving assembly robot with feedback on how much force is being applied or how well parts are being put together. Altogether, these sensing technologies make the use of robots in an assembly line cost effective even for short production runs.

The uses of assembly robots

The application of assembly robots is used in various industries including putting together automotive components such as gearboxes, pumps, and motors. Another excellent area is consumer electronics and computer as well as household appliances and medical devices. This type of robot is ideal for tasks that demand both speed and precision such as applying adhesives and sealants. They can not only work quickly and accurately without getting tired but also assemble parts that are either too intricate or small for humans.

Assembly robots are also useful for tasks where cleanliness is paramount such as medical device assembly and pharmaceuticals. Unlike humans, they are also not prone to getting weakened by injuries such as carpal tunnel syndrome which is brought about by doing repetitive work.

The beauty of assembly robots is that they boost both capacity and quality while lowering production costs. They are also flexible, unlike dedicated automation equipment. These off-the-shelf machines can be reconfigured and deployed anywhere they are needed. Above all these, an assembly robot is a piece of mature technology that promotes low-risk and high-return investments.

Have you read?

These 15 Universities Produce The Most $1 billion Business Startup Founders.

World’s Best Universities For Sports Science In 2018

Best Universities To Study Architecture And Interior Design In America, 2018.

World’s Best Colleges And Universities For Engineering And Technology, 2018.

Best Universities In The Arab World For 2018.

Bring the best of the CEOWORLD magazine's global journalism to audiences in the United States and around the world. - Add CEOWORLD magazine to your Google News feed.

Follow CEOWORLD magazine headlines on: Google News, LinkedIn, Twitter, and Facebook.

Copyright 2025 The CEOWORLD magazine. All rights reserved. This material (and any extract from it) must not be copied, redistributed or placed on any website, without CEOWORLD magazine' prior written consent. For media queries, please contact: info@ceoworld.biz