Connected Agriculture – how IoT technology is deployed to improve food production and distribution

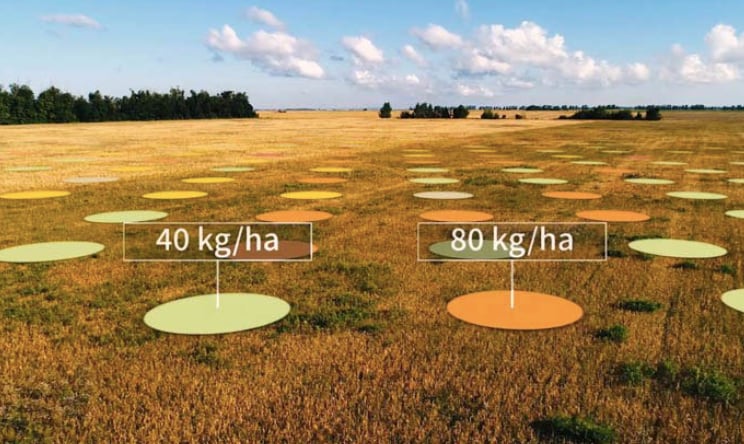

The cost of IoT sensors has halved in the last 10 years and is still on a downward trend. Sensors can monitor the chemical composition and moisture content of the soil in each part of a farm as well as the rainfall and temperature. By combining this data with detailed weather forecast information and fertiliser recommendations, each farmer can improve yields through the effective deployment of expensive chemicals, and also reduce water usage. Efficiencies can be made in other parts of the process using ‘connected’ technology in the control of agricultural machinery and for crop monitoring collection, storage and distribution.

The range of technology to achieve these aims should not be underestimated; a good example is the partnership between IBM and Yara. IBM provides weather monitoring – through The Weather Channel, which it owns, and AI (Artificial Intelligence), machine learning and analytics – through its Watson capability. Yara has over 100 years of experience in agronomics and, more recently, in using digital farming for the optimum use of crop nutrition products. Together, they are developing a digital farming platform that will, according to Terje Knutsen, EVP Sales and Marketing in Yara: “empower professional and smallholder farmers to optimize farming practices to increase yields, crop quality and incomes in a sustainable way.”

Earlier this year, IBM and Yara unveiled the Open Farm & Field Data Exchange to bring data together from farmer associations, industry players, academia and NGOs from the food and agriculture industry. According to IBM, the agriculture industry needs to invest in exponential technologies such as AI, IoT, and big data to help address climate change and population growth as it threatens the world’s ability to produce enough food. Together with Yara, IBM is taking a major step towards transforming the global food system by inviting all food value chain players to join this movement to help feed the world more efficiently and sustainably.

Cambashi also spoke with Luq Niazi, Global Managing Director, Consumer Industries for IBM, who told us about the IBM Food Trust, a blockchain-based food safety solution that uses a digital ledger to improve food traceability and safety in the supply chain. The IBM Food Trust is a decentralized platform to optimize the supply chain and increase freshness, improve food safety, minimize waste and provide provenance of the food. Food retailer Carrefour recently joined Nestle and IBM to provide this capability in France. IBM aims to combine this with the digital farming platform to provide a comprehensive solution with wider potential.

Other ‘connected’ applications are also being applied to agriculture; Colin Elkins, Global Industry Director, Process Manufacturing at IFS, lists the following technologies that are being introduced:

- Planting drones – Dendra Systems (previously called BioCarbon Engineering), a U.K.-based start-up, has developed a technique that has already planted more than 25,000 trees across the globe using drones.

- Autonomous harvesting – Harper Adams University, based in Shropshire UK, and Precision Decisions, recently acquired by Map of AG, are creating a ‘Hands Free Farm.’ The aim is to be the first in the world to grow, tend and harvest a crop without operators in the driving seats or agronomists on the ground. The project has already been taken through two successful cropping cycles and recently won the BBC Food and Farming Future Food Award.

- Analysis, monitoring, spraying and inspection by drones – Drones are already changing the face of UK agriculture and are expected to be worth around the $22 billion by 2020. Farmers have been using drones for many years, but with recent advances in drone technology by companies like DJM Aerial Solutions of Middlesbrough, UK, the farming industry is now able to adopt drone use as part of their precision agriculture.

In addition to the above CNH Industrial, using PTC technology, has continued to evolve autonomous tractor concepts under its Case IH and New Holland brands. It is now implementing pilot programs to study autonomous vehicles in real-life farming situations.

Hexagon, a global leader in sensor, software and autonomous solutions, provides advanced ‘connected’ agricultural technology to 38 countries on five continents. This includes a smart, integrated platform that enables agricultural and forestry companies to manage, plan, monitor and optimize cultivation, harvesting and transport and create a digital twin of the physical world using its ‘Smart Digital Reality™.’ Bernardo de Castro, president of Hexagon’s Agriculture division, said at Agritechnica 2019; “Hexagon’s AgrOn Ti7 display helps solve the incompatibility between tractors, implements and computers, and ensure synchronization between all technological solutions, making the processes more efficient. Remote service makes troubleshooting quick and economical due to time savings by reducing technician travel.” Hexagon supplies many large agricultural companies, especially in the grain, sugar-energy and forestry sectors, including São Martinho, one of the largest sugarcane mills in the world.

Aquaculture – the extension of agricultural methods into seas, rivers and lakes – is also growing strongly using IoT technology. SHM Enabling Technologies AS of Ålesund, Norway, has developed and installed a centralized fish feeding system that uses distributed controls from a central console to control the feeding machines (‘blowers’) using Connext DDS from RTI. Existing sensors and cameras are re-purposed and a central console installed to allow a single manager to manage a number of fish farms.

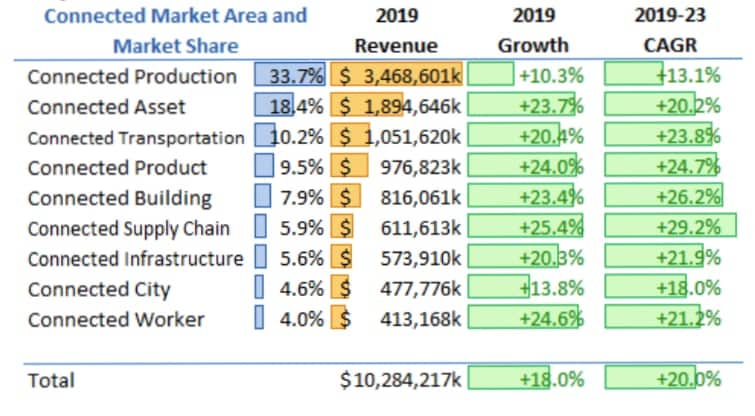

Cambashi’s research into IIoT and Connected Applications highlights the global trend in Connected Production where the main software application revenues of IoT in agriculture are recorded. This shows that in 2019, Connected Production constituted just under $3.5 billion US dollars out of an overall revenue of $10.3 billion USD, and the CAGR is projected to be over 13% for the next four years. Other connected applications such as Product, Asset, Transportation and Supply Chain also apply to agriculture in different ways.

The main providers of this technology come from very different backgrounds, such as IT (‘Information Technology’) – Amazon AWS, IBM, Microsoft, Oracle, SAP, OT (‘Operational Technology’) – ABB, Bosch, GE, Honeywell, Rockwell, Siemens, Schneider), ET (‘Engineering Technology’) – Autodesk, Dassault, PTC, and specialist IoT providers like RTI and CISCO.

See Figure 2, below for detailed results and projections:

IoT in agriculture, whether applied through Connected Production or other applications, is already established and beginning to grow quickly. This is just one area where industrial IoT technology is moving from the hype stage to reality, and this is also beginning to happen in other industries.

Bring the best of the CEOWORLD magazine's global journalism to audiences in the United States and around the world. - Add CEOWORLD magazine to your Google News feed.

Follow CEOWORLD magazine headlines on: Google News, LinkedIn, Twitter, and Facebook.

Copyright 2025 The CEOWORLD magazine. All rights reserved. This material (and any extract from it) must not be copied, redistributed or placed on any website, without CEOWORLD magazine' prior written consent. For media queries, please contact: info@ceoworld.biz