Protecting Additive Manufacturing Workflow with Blockchain Technology

Each December, CEOWorld magazine identifies the top five technology trends poised to transform the world in the New Year. In 2018, Blockchain and Additive Manufacturing/3D Printing were two digital platforms recognized for the dramatic impact they have on global enterprise, particularly in leading industries such as manufacturing, government, and supply chain. As more industries are realizing the benefits of additive manufacturing (AM), it follows that the transportation, distribution, and security of the digital files AM generates using blockchain-enabled solutions are gaining momentum for the future of business in the fourth industrial revolution or Industry 4.0.

The products produced by AM technology are only as viable as the integrity and traceability of the digital files – and printers – that create them. Unsecured data carries with it a greater risk for counterfeit, maliciously modified, poor quality, or uncertified parts entering the physical supply chain. For the manufacturing sector the threat is real as the third most targeted sector for cyberattacks after the government and financial sectors. For this group, unsecured data and parts can represent lost revenue, safety risks, and the theft of valuable intellectual property (IP). For the government, counterfeit parts can impact national security: supply chain integrity and counterfeit parts are two top concerns cited by the Department of Defense (DoD) in its last Annual Defense Industrial Capabilities Report.

Fortunately, there is a consortium helping to connect these various industries for the purpose of developing, demonstrating, and successfully transitioning innovative technologies like AM and blockchain efficiently, with less risk and lower cost known as the National Center for Manufacturing Sciences (NCMS). Established 32 years ago by executive order to improve the strength and competitiveness of the U.S. industrial base, NCMS’ network of leading industry, government and academic partners is currently investigating how blockchain-enabled security solutions can improve the AM digital supply chain and facilitate new manufacturing and sustainment models by including data integrity, compliance rights, feedback monitoring, counterfeit mitigation, and revocation.

Enhanced transparency, scalability, and trustworthy systems limiting the risk of unauthorized intervention are some of the advantages afforded by blockchain technology in the supply chain.

Blockchain is ideal for processes involving real-time data, multiple handoffs and need for flexibility. Adapting this technology to the data generated by an AM digital supply chain requires an enterprise-wide commitment to understand the business need/problem and a human-centered, design-thinking focus tailored to the end-users comprising each phase or gate in the chain, beginning with the design and engineering phase.

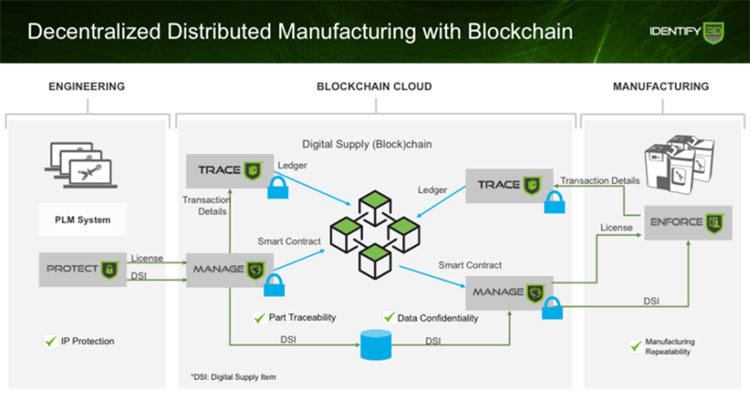

DESIGN AND ENGINEERING

Top OEMs have well-defined processes for the design, testing and prototyping of their products. The digital files associated with the final design, and the engineering data for building it, are highly valuable assets requiring protection with encryption. For parts to be built with AM technology, a digital supply item or DSI can be generated for each part and serve as the encrypted digital vessel to prohibit unauthorized access ahead of its decryption by an AM machine.

A digital licensing agreement is established by the IP owner during this phase to define the usage parameters of the digital design and engineering files, including who has access to the data, the duration of that access, as well as detailed instructions for creating the final product. Examples of the latter include the AM machine to be used, feedstock material selection, finishing instructions, and the number of parts to be produced.

DISTRIBUTION

In a traditional, centralized manufacturing process one organization is responsible for creating the design files, manufacturing the parts or product, and the distribution. In a decentralized, digital supply chain process those responsibilities can now be delegated in a secure manner. Using blockchain technology, the encrypted digital files and digital license pass to the authorized partner(s). Depending on the security level required, files may be transmitted from one system to another via email, an off-line system, or direct access to the company server.

Smart contracts within the blockchain support this decentralized business process and relationship agreement. Gaining momentum as a credible means for making this new type of business relationship viable, the smart contract or small software program, contains the specific terms and rules of the agreement. Using a smart contract-enabled blockchain, the digital distribution license can be authenticated, transported, and recorded by blockchain transactions. The overall fulfillment of the smart contract is essentially guaranteed by the blockchain technology, allowing all blockchain members to participate and enforce the distribution and asset management rules set by the smart contract. The benefits of smart contract use mirror blockchain technology use, through enhanced security, trust, distributed storage, tracking, and efficiencies.

MANUFACTURING

The digital supply chain model supports authorizing multiple manufacturers’ use of the digital files for part production in keeping with the terms of the smart contract licensing agreement. The technology enforces the build parameters previously set by the IP owner during the design and engineering phase. Each manufacturer is required to meet all the build parameters detailing the AM machine make and model, feedstocks, etc. before access and decryption are granted. Additionally, production rules associated with the licensing agreement support a high-quality build and prevent fraud associated with counterfeits by controlling the number of parts a particular manufacturer is authorized to print.

IN-MARKET

Ensuring there is a digital means of tracking and tracing parts back to their originating manufacturer (AM machine designer and engineer) following market release is another important facet of protecting AM workflow with blockchain technology. Coding or digitally tagging parts and recording it on the blockchain ledger connects the physical part to the digital data files that were used to create it. RFID, chemical trackers, and serialization numbering are a few of the options available. Storing information on the blockchain ledger also supports the organization’s continuous improvement process through performance modeling and failure simulations.

NCMS Senior Project Manager, Dana Ellis, said the blockchain will store information across each phase – design/engineering, distribution, manufacturing, and in-market – on participating nodes or the electronic devices authorized to connect to the blockchain network. He offers additional reasons supporting blockchain technology for protecting AM workflow. “All transactions within a block of data are cryptographically hashed along with the previous block to form the current block, preventing data modifications that would compromise the integrity of the entire chain. Any data modifications would compromise the integrity of the entire chain, and since the blockchain network is governed by the consensus, the authenticity of any transaction can be rejected as a fraudulent transaction.”

FUTURE

The need and desire for accelerated, high-quality production, faster time-to-market, and reduced storage requirements continue to propel the adoption of advanced manufacturing technologies like AM and decentralized manufacturing models. Successfully adapting blockchain technology for AM and then adopting the best practices it offers for securing and authenticating the data stream AM generates within a digital supply chain represent the next frontier of secure manufacturing and the new distributive manufacturing ecosystems that accompany it.

Bring the best of the CEOWORLD magazine's global journalism to audiences in the United States and around the world. - Add CEOWORLD magazine to your Google News feed.

Follow CEOWORLD magazine headlines on: Google News, LinkedIn, Twitter, and Facebook.

Copyright 2025 The CEOWORLD magazine. All rights reserved. This material (and any extract from it) must not be copied, redistributed or placed on any website, without CEOWORLD magazine' prior written consent. For media queries, please contact: info@ceoworld.biz